Aluminum is widely used in industry for its lightweight, its durability and its high corrosion resistance.

Aluminum alloys have been developed for decades to meet industry requirements, and they are nowadays indispensable for all markets including the automotive industry, aircraft and aerospace, building & construction, electronic and many more.

This versatile material can be processed in many ways: casting, extrusion, forging, sheet & foil and offers endless design possibilities.

Gravotech can follow you throughout your projects and provide laser and rotary solutions perfectly adapted for this soft material. You can use our solutions to mark, engrave, cut, modify & personalize your parts.

Gravotech has a lot of experience on aluminum engraving and can provide the best solution depending on your application:

- Permanent and high-contrasted marking on all kinds of aluminum: raw, aluminum alloy, coated or painted aluminum.

- Marking, etching and engraving of serial numbers, 1D /2D codes, QR codes and logos directly on your parts.

- Compact, independent, and fast marking laser & dot peen machines for identification & traceability of your parts directly in your production line.

- Aesthetic deep engraving with our engraving laser and rotary machine.

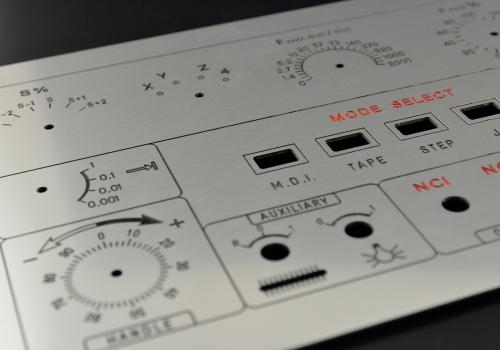

- Create your objects like machine front panels with our mechanical solutions allowing to cut, drill, engrave on aluminum.

- Personalize aluminum objects directly in store with our compact laser and rotary engraving machines. Mugs, pet tags, mobile phones casing all aluminum shapes can be engraved.

Gravotech's aluminum engraving machines

Discover our range of lasers suitable for marking aluminum! This type of metal can be marked perfectly and quickly with our laser solutions.

Integrated laser system to mark and engrave on all metals.

FIBER Laser

Medium fully automated laser marking station.

LW2

Large fully automated laser workstation with Fiber, Hybrid or Green sources

LW3

Small laser engraver for all kind of engravings.

WELASE

Gravotech’s Dot Peen marking machine and scribing solutions offer non-contrasted, visible and deep marking obtained by making close impacts on the surface of several steel types. Rotary engravers are ideal for aluminum personalization in-store, as they are compact, silent and easy to use. Discover our large variety of jigs to easily hold any part.

The fastest pneumatic dot peen marking machine.

XF510p

The most precise and consistent electromagnetic dot peen marking machine.

XF510m

The quiet metal scribing marking machine.

XF510r

Medium CNC engraving machine for flat and cylinder engraving on metal and plastic.

IS400 and IS400 Volume

Large and extra large format CNC engraving machines.

ISx000

Small and custom engraving machine for all purposes, from perfume bottle to small industrial signage.

M20 X

Standalone dot peen marking station.

IMPACT

Small CNC engraving machine for label and small part traceability system.

IS200

Lasertrace™ facilitates the traceability and identification of all types of parts. Gravostyle™ allows you to easily create your customized engraving jobs. Unleash your creativity and conquer new markets.

Aluminum engraving: laser or rotary technology?

With our lasers you can either laser etch aluminum or laser engraving aluminum: our aluminum laser engraving machines provide a high contrasted, permanent marking at a very short cycle time on the surface of the aluminum.

Thanks to the combination of high average power and high peak power, our fiber lasers and hybrid lasers are adapted to texture the surface of the aluminum part. Galvo laser can be used to have a deep engraving on aluminum material.

We can obtain localized thermal vaporization of the material quickly as the melting point of aluminum is low compared to other metals. Just repeat several passes to remove several layers and reach the desired engraving depths.

Additional settings like the vector filling angle can be modified between each pass to obtain smooth surfaces and a perfect marking rendering with cleaning and finishing passes can be added to remove melt ejections & obtain a higher contrast.

Benefits of laser technology on aluminum :

- Can be used on different types of aluminum.

- Grey surface markings when short cycle time is needed.

- Deep engraving is easily achievable into the aluminum.

- Galvo laser can be used to modify the surface finish of a part.

- Aluminum laser engraving is permanent and resistant to high temperatures, coating and surface treatments such as shot blasting.

See our aluminum laser engraving machines.

Gravotech offers 2 rotary technologies for datamatrix marking, text and numbers engraving :

Dot peen marking machines allows a visible, high-speed and permanent marking that ensures full & tamperproof traceability of your parts. We provide a full range of stylus to achieve a light to deep engraving, mark from flat to uneven surface.

Scribing marking machines allow precise, deep and silent engraving. The stylus penetrates the material and then, moved from X to Y marks, it scribes the surface of the part and performs the marking. Benefits of dot peen/scribing on aluminum :

- The clean solution, no precautions for use: no dust, no fumes.

- Consistent marking regardless of the type of aluminum.

- Best marking depth/cycle time ratio among all possible marking solutions on the market.

- Marking depth up to 0.5 mm.

- Long lifespan on the tool because aluminum is very soft.

- The lowest operating cost on the market.

- A robust machine that can mark on aluminum with high temperatures, both after rolling and after extrusion.

Aluminum engraving with a rotary engraving machine is a simple solution to install and use. Our engraving stations are great for personalization on aluminum products or small unit work.

Our CNC Stations provide large format aluminum engraving and cutting for both unit work but also batch engraving and cutting on a single aluminum sheet

Benefits of rotary on aluminum:

- A wide range of tools available so you can engrave or cut, whatever the project.

- Compact: Small rotary engravers have a small footprint and do not require any additional equipment. They are therefore ideal for environments where space is at a premium, such as stores, counters, shopping center corners and so on.

- Precise control of the engraving depth.

- Cuts faster than laser with clean straight edges.

- Tried and tested technology used worldwide.